Period of use / Climate condition

- Home

- Water Proofing

- Waterproofing Products

- Bitumen Membrane

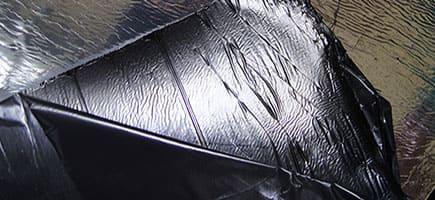

- Implementation of Bituminous Membrane

- Period of use / Climate condition

Characteristics of Bituminous Membrane

Period of Use/ Climate Condition

Some types of product carry a symbol of a sun or a pine-tree printed on the strip at the bottom of the packaging, to identify the period of use for which the membrane was made and in which it is advisable to use the product. It is advisable to apply membranes with the sun symbol during the summer months, and those with the pine-tree during the winter.

Failure to comply with the recommended application period does not reduce the efficiency of the finished membrane, but creates drawbacks and disadvantages when laying, such as excessive softness of the winter membrane when applied in the summer, and excessive stiffness and difficulty in unrolling the rolls of the summer product when used in the winter. The products should therefore be applied in favourable atmospheric conditions.

Rain, frost, snow and high humidity can interfere with the adhesion of the membrane to the substrate and at the overlaps. With temperatures below +5°C it is very likely that there will be ice on the surface to be covered, and the rolls will be more difficult to unroll. As a result, moisture trapped between the membrane and the substrate can give rise to the formation of bubbles. In these conditions it is better not to apply the material. In summer, in hot countries, and especially when it is being laid over thermal insulation, it is advisable to apply the material in the coolest part of the day, avoiding the hours in the middle of the day when the sun is at its hottest.

Applicable Scope

There are 2 methods in applications

By heating and melting method

By cold adhesive method

Features

- Good ability is of anti-aging, anti-alkali, resistant to high temperature. High tensile strength and elongation, which adapts to the contraction or crack of the base.

- Total impermeability for total waterproofing.

- Excellent resistance to aging and weathering.

- Outstanding bondability and seam integrity.

- Flexibility at low temperature.

- Stability at high temperature.

- Very high resistance to impact & puncture.

- Application friendly. (Labour cost saving)

- High tensile strength and tear resistance.

- High tensile strength and tear resistance.

- Isotropic properties.