Nurproof

- Home

- Products

- Bitumen Liquid Membrane

- Nurproof

Nurproof

Nurproof

Elastomeric SBS Modified Bitumen Coating

Advantages of Nurproof

- Cold & liquid applied, no heating required

- No joints, forms elastomeric membrane

- High-build properties ensure rapid application

- High elasticity, ensuring a permanently flexible barrier over a wide range of temperatures

- Asbestos free product. Can be applied in closed and confined spaces.

- Excellent adhesion, can be applied to a range of substrates

- Easy application due to paintable consistency, suitable for new and old concrete.

Typical Technical Data

| Color | Black |

|---|---|

| Solid content | 50 % ± 5 |

| Specific Gravity | 0.98 ± 0.02 @ 25 C |

| Elongation | > 800% |

| Tensile strength | 2.5 N/mm2 (ASTM D 412) |

| Service Temperature | -10 C to 85 C |

| Application temp | 50 to 450 C |

| Cure time @ 250 C | 24 hours per coat |

| Chemical Resistance | Salt solutions, mild detergents Acids and Alkalis |

Typical Application

Application

Nurproof should be applied by brush to obtain a continuous unbroken film. 2 coats are required with the second coat applied at right angles after the first coat has cured. Nurproof must be protected from mechanical damage during subsequent construction or backfilling works. Any damage may be repaired by spot application. If a water flood test to be run, the membrane should be cure for a minimum of 10 days. Whilst Nurproof is resistant to frost, adhesion will be impaired if applied to frosted substrates. Application should be avoided if substrate temperatures are below 50 C or rain is imminent.

Instructions For Use

Surface Preparation

All substrates must be sound, clean, dry, smooth and free from protrusions, voids, honey-combs and high spots. Presence of curing agent, paint and oil will impair adhesion. The moss and lichen must be removed and area treated with proprietary fungicidal wash to kill spores and inhibit further growth. Following treatment wash area thoroughly with clean water and allow to dry. Fillets must be provided at corners or sharp angles using 4:1 sand and cement mortar modified with a good quality bonding agent.

Priming

Priming is not normally required on good quality, well prepared substrates.

Cracks

All shrinkage and non-structural cracks must be treated with not less than 1.5 mm coating of Nurproof extending 75 mm either side of the crack. Allow to cure overnight prior to general application.

Health & Safety

Nurproof contains flammable solvents. As with all chemical products, care should be taken to avoid contact with skin, eyes, mouth and foodstuffs. Treat splashes to eyes and skin immediately, by thorough washing with clean water. If ingested seek medical attention.

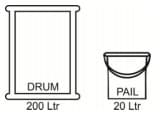

- Packing: 200 Liter Barrel, 20 Liter Pails

- Coverage: Apply the coating at a coverage rate of 1-2m²/Lt, Depending on the dry film thickness required. 550 micron dry film thickness (DFT) can be achieved when applied at 1.1 Lt/m²/coat.

- Standard Compliance: Nurproof complies with ASTM C 836 Standard Specification for high solids content, cold liquidapplied elastomeric waterproofing membrane.