Nurpaint

- Home

- Products

- Nurpaint

Bitumen Paint- Nurpaint

Black Bitumen Paint

Bituminous paints are made of bitumen or coal tar which is dissolved in mineral spirit or naphtha. Bitumen is also known as asphalt which is sticky, black, and highly viscous liquid or semi-solid form of petroleum.

Bituminous paint is a type of bituminous coating product that provides weatherproofing and corrosion resistance to the elements. It has good adhesive properties. A bituminous coating is used to build a vapour-proof and protective coat in accordance with its formulation and polymerization grade. The bituminous coating is also known as asphalt coating.

Bituminous paint is strong, waterproof, durable and economical. It resists manufacturing harsh chemicals and UV light. It also protects surfaces from rust.

Bitumen paint waterproofing is a solvent based, full bodied black bitumen paint, when dry, the product is odorless and taint free bitumen film.

Uses of Bituminous Paint

- Bituminous Paints are alkaline resistant hence it is used for under water structure, weather protecting steel work, waterproofing, wood, concrete and potable water tanks.

- It is also used for any exterior metal work and iron work such as fire escapes, ladders, gutters, down pipes, railings, fences and gates, etc.It is used to coat ferrous metals, non-ferrous metals and other construction materials, even in marine environments.

- It is a flexible coating solution that can be used both above and below ground.

Nurpaint (Bitumen Paint) - Typical Characterstics & Product inforamtion

| Property | Standard Specification |

|---|---|

| Color | Dark - Brown |

| Form | Thick - Viscous liquid |

| Density | 0.9 g/cm3 at 20°C |

| Type of Solvent | White spirit |

| Flashpoint | 40°C |

| Film Thickness Per Coat @ 11m² / Lt | Wet - 0.1mm Dry - 0.05mm |

| Chemical And Water Resistance | Resistant to: most salt solutions, dilute acids and alkalis, water and alcohol. Not resistant to: oils, solvents and some detergent solutions |

| Application Information | |

|---|---|

| Consumption / Yield | Porous surfaces: 4-6m² Non-porous surfaces: 11m² |

| Ambient Air Temperature | > 5°C - 40°C. Surfaces must be free from ice and water. |

| Drying time | 4-6 hours depending on drying conditions |

| Product Information | |||

|---|---|---|---|

| Shelf Life | 24 months from date of manufacture in tightly sealed, undamaged containers. | ||

| Storage Conditions |

Contains a flammable solvent; all normal precautions against fire must be taken during both storage and use. Store in the original container in cool (5°C - 25°C), dry conditions. Keep away from sources of ignition. |

||

Instructions For Use

Substrate Preparation

As with all surface coatings, preparation of the surface is of great importance and will influence the degree of adhesion obtained and the life of the coating. All surfaces must be sound, stable and thoroughly clean and dry. Metal surfaces should be wire-brushed to remove rust. Where long-term protection is required an initial treatment of a rust-inhibitive product such as red lead or zinc phosphate should be used. Loose or blistered paint should be removed, as should tar-based paint systems. New galvanised surfaces should be roughened with a wire brush or treated with a proprietary etch primer. Porous surfaces should be primed with Nurprime-WB

Application

Nurpaint (Bitumen paint) is ready for use and should not be thinned. Stir thoroughly before use. Apply by brush or spray. A minimum of two coats of Nurpaint should be applied. The first coat should be allowed to dry (normally 2-4 hours depending on weather conditions) before the second coat is applied.

Protective coating on concrete, etc: since concrete and some stone surfaces may be porous, an initial primer coat of Nurprime primer should be applied.

Cleaning of Tools

Tools may be cleaned by using white spirit. Any spillage should be wiped off surfaces before the bitumen paint has set.

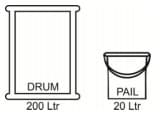

- Packing: 15Ltr, 20Ltr Metalic Pails, 200Ltr Steel Drums